The manufacturing process starts after the membrane details, welding and membrane plate types are determined according to the project specifications and static calculations.

| SURFACE CONTROL AND CUTTING The membrane rolls received from the manufacturer go through surface controls against deformations and flaws that may occur on their surfaces during the manufacturing phase. The materials received as rolls are cut with +/-1mm accuracy in CNC-controlled automatic machines in compliance with the cutting panels formed. The edge pocket and wick making processes start while the templates cut are taken to the production line for welding. |

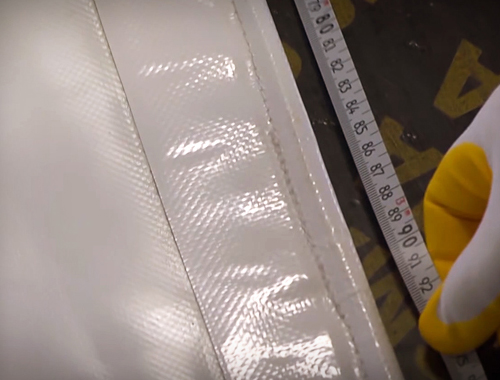

| HIGH FREQUENCY WELDING The patterns are welded in High Frequency machines to provide high welding strength. |

| MEASURE CONTROL The patterns are controlled for conformity to the project measures following the HF (High Frequency) welding process. |

| PACKING The fabrics passing the measure control are packaged carefully in accordance with the installation planning. |

| TRANSPORTATION The packaged PVC membrane materials are sent to the construction site for installation. |