| MATERIAL SUPPLY The materials ordered in specified quality, standard and printing arrive in our factory as a roll. |

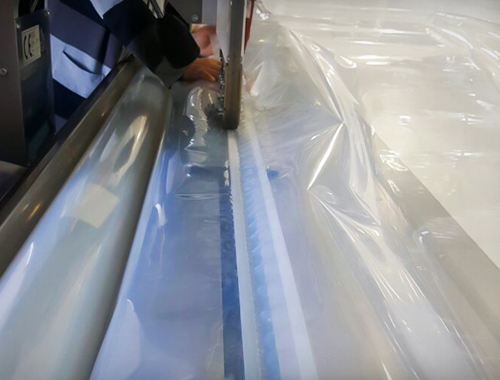

| CNC CUTTING PREPERATION The ETFE films are laid suitably on the cnc machine for cutting the templates obtained based on form and air pressure values to be applied. |

| MEASURE CONTROLLED PLACEMENT A size-controlled sensitive placement is ensured to prevent the cutting templates from going out of the material. |

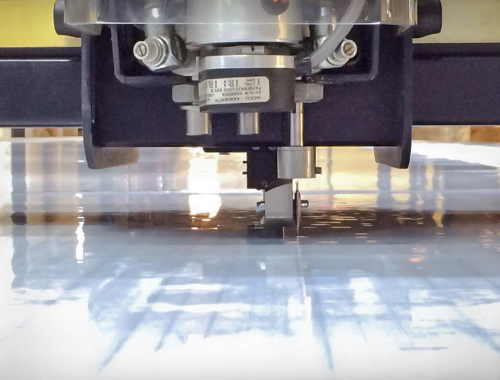

| CUTTING The ETFE film is cut with +-1mm accuracy. |

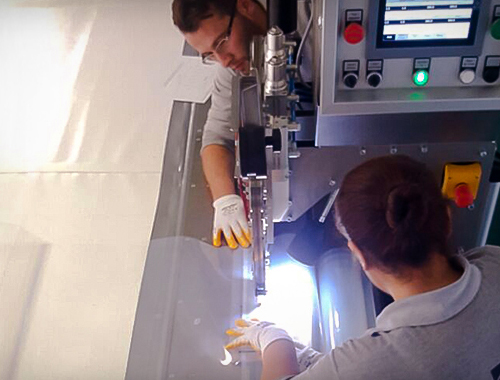

| WELDING The interim unit welding process of the cut templates is made according to the shares given. The parts are welded according to template numbers and module sizes to form a whole. |

| INNER ROPE SETTLEMENT A pocket welding process for ropes is used to increase the statical strength of the ETFE film (in single-wall applications). |

| POCKET WELDING It is the process of making a wide pocket so that the ETFE film's edge ropes can pass through easily (in single-wall applications). |

| WICK WELDING The process in which all layers of the EPDM wicks, which are placed on the edges of modules, are welded simultaneously in order for the ETFE film to be assembled to the special-extrusion aluminum profiles (in single-wall, double-wall, three-wall, four-wall applications). |

| PREPERATION FOR PACKING The packing preparation is carried out according to module measure, size and assembly opening status. |

| PACKING Packing of the material and labeling it with the module identity and series to prevent losses following the form of folding that will minimize the breaking and tearing risk. |

| SHIPMENT Maximum safety is provided for the materials packed during the shipment by being placed in crates or counters. |