ETFE (Ethylen Tetrafluoroethylen) is a material with fluoro-polymer quality. It was developed by Dupont company for aircraft industry, but has turned into a product used in today's architecture for its light permeability and lightness. It is generally applied in the form of 2- or 3-layered inflatable airbags or sometimes as a single wall. The ETFE material is quite thin and lightweight. It weighs nearly 1% of the glass, and has become more prominent as it has more light permeability, the self-cleaning feature and convenience of application. The strength is highly increased when an air-inflation system is used in ETFE systems.

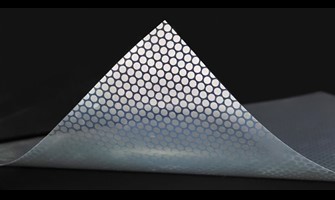

ETFE (Ethylen Tetrafluoroethylen) is a material with fluoro-polymer quality. It was developed by Dupont company for aircraft industry, but has turned into a product used in today's architecture for its light permeability and lightness. It is generally applied in the form of 2- or 3-layered inflatable airbags or sometimes as a single wall. The ETFE material is quite thin and lightweight. It weighs nearly 1% of the glass, and has become more prominent as it has more light permeability, the self-cleaning feature and convenience of application. The strength is highly increased when an air-inflation system is used in ETFE systems.The ETFE systems are assembled with special Aluminum profiles on a carrier carcass system. The system is fed by blowers in inflatable cushion systems, and the bearing function of the ETFE inflatable cushion systems is continuously enabled by re-activation of the system in case of a leakage or an extra pressure requirement.

It is required to take into consideration the climatic conditions, aesthetic, acoustic and environmental factors while designing the ETFE systems. Form, printed or 2- or 3-layered ETFE inflatable cushions must be used based on the requirement & service criteria.